Articles

-

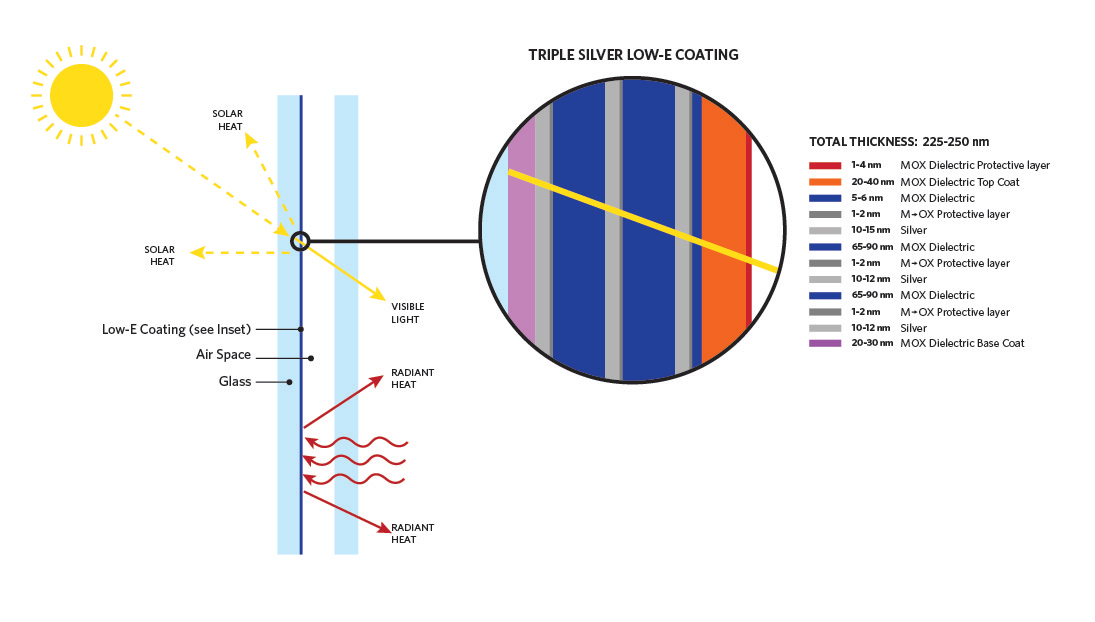

WHAT IS THE MOST IMPORTANT FEATURE FOR TRIPLE SILVER GLASS TEMPERING?

In my opinion it is that the convection air must be heated into the matrix configuration. The reason is, that the silver glass reflects almost 100% of the radiation. Only convection guarantees uniform glass temperature. At the same time as the convection is heated, the capacity is increased. Actu...Read more -

Tips and More about Glass Fabrication

Thanks for checking in today. Before we get started there are a couple of items that must be addressed. We give them a whole lot of lip service but is that all it is? We must live and breath these guys or all that follows will be vastly diminished and any improvement gained will not hold long ter...Read more -

Effects of return air flow for convection heating

Modern convection technologies have been manufactured now over 20 years. The real very good convection system was developed kind of accidentally. It was using of famous radiation heating furnace of Tamglass Engineering, HTF and adding high convection into that. The furnace was named “CONVAIR”, ...Read more -

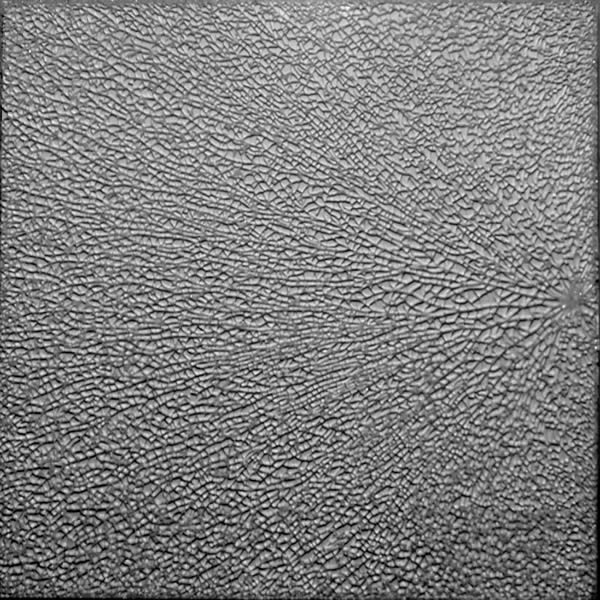

Does the shard size of tempered glass vary depending on the impact strength?

It is a very known behavior that the glass fragmentation depends on where you break the glass. This week, we’ve received the following question from Middle East: I have observed that when we break glass in the center with a lot of force, the fragments close to the point of impact are sometimes b...Read more -

What causes the streaks (rope marks) in my shower glass?

Question: My shower glass has the rope marks (streaks) in the glass running up and down. The issue shows up when the glass gets foggy after showering. What causes this effect? Answer: Most likely the effect is coming from the tempering process when glass in contact with kevlar cords in the quench...Read more -

Debates and discussion on what to decide the good tempering furnaces and factors to produce the good quality of tempered glass.

Debates and discussion on what to decide the good tempering furnaces and factors to produce the good quality of tempered glass. Mujash (Supply Chain Professional): more interesting way to take forward if you ask specifics. pros and cons of each furnaces. – Glaston, EFCO, uniglass, quite a ...Read more -

How to select glass sheet prior to the tempering process?

It is so important to select the qualified glass sheet before glass processing, i.e. tempering. Defective glass sheet may lead to quality issues and shattering during the process. Avoid using glass sheet containing stones. Especially in the tensile stress area, even tiny stones could become the c...Read more -

How to maintain the chillers of the glass tempering furnace?

The chiller of the glass tempering furnace consists of a roller table and two chillers. One chiller is on the top and the other one is at the bottom of bed. Once there is an explosion in the chiller, the glass debris could damage the aramid kevlar ropes over the roller table, affecting smooth tra...Read more -

Counting of Fragments in Tempered Glass Fragmentation Test

The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass. Even though the way to count the number of fragments is defin...Read more -

Stress Mark on Tempered Glass

Stress marks may be remained on the tempered glass, which are usually caused by the reflection under the polarized light, such as sunlight or other forms of reflected light. The colors of the stress marks are sometimes referred to as iridescent, or the general condition as iridescence. Sometimes...Read more -

How the production affects the glass cutting process

Everyone who processes this material knows that laminated safety glass (LSG) is unconventional and requires a great deal of sensitivity. The LSG cracks and chips and finally the question arises: What was to blame for the breakage? Was the cutting pressure too low? Was the crushing pressure too h...Read more -

The challenges of bus side window manufacturing today

Electric buses, reduction of emissions, advanced safety systems and even autonomous vehicles were all popular topics at the Busworld exhibition this year in Brussels. Save for a few new innovations, the glazing solutions on display were quite conservative. However, a range of integrated displays...Read more